It is vital to make sure that products are safe for the environment and human health in our increasingly environmentally concerned society. RoHS is one important standard that makes this possible. For businesses in the electronics sector and beyond, RoHS testing is a crucial procedure. This blog discusses what RoHS testing entails, why it matters, and how it affects both consumers and manufacturers.

Understanding RoHS Compliance

What Does RoHS Stand For?

RoHS stands for Restriction of Hazardous Substances. It is a piece of legislation by the European Union that restricts the use of specific hazardous materials found in electrical and electronic products. All applicable products in the EU market must pass RoHS compliance.

The Substances Restricted by RoHS

RoHS specifically restricts the use of ten substances: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE), bis(2-ethylhexyl) phthalate (DEHP), butyl benzyl phthalate (BBP), dibutyl phthalate (DBP), and diisobutyl phthalate (DIBP). These substances are hazardous to the environment and pollute landfills, and are dangerous in terms of occupational exposure during manufacturing and recycling.

The Importance of RoHS Testing

Protecting the Environment

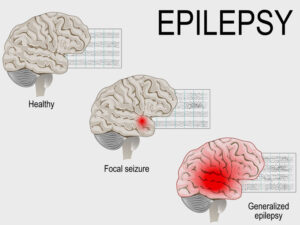

One of the primary reasons for the introduction of RoHS was to prevent hazardous substances from causing environmental damage. When electronics are improperly disposed of, the restricted substances can leach into the soil and water, harming wildlife and affecting human health. RoHS compliance helps to mitigate these risks.

Improving Consumer Safety

RoHS compliance also plays a crucial role in consumer safety. By restricting harmful substances, RoHS testing ensures that the electronics consumers buy are free of materials that could potentially release toxic substances. This is particularly important for items that are in regular contact with users, such as smartphones and laptops.

Enhancing Waste Management

With the growth of electronic waste (e-waste), managing this waste has become a significant challenge. Electronics that comply with RoHS are easier to recycle, and the toxicity of the waste is significantly reduced. This compliance supports the efforts towards a more sustainable approach to e-waste management.

How RoHS Testing Is Conducted

The Testing Process

RoHS testing is usually performed by certified laboratories that specialize in environmental compliance testing. The process involves several steps:

- Sampling and Preparation: Samples from the product are prepared for analysis, which might involve disassembling the product to access various components.

- Screening Tests: Initial screening tests are performed to quickly check for the presence of RoHS substances using methods like X-ray fluorescence (XRF) analysis.

- Laboratory Analysis: More detailed analysis is conducted to accurately measure the concentration of restricted substances. Techniques like Fourier Transform Infrared Spectroscopy (FTIR) and Gas Chromatography-Mass Spectrometry (GC-MS) may be used.

Documentation and Certification

Upon successful testing, the product is certified as RoHS compliant. Manufacturers must keep records of compliance, including test reports and supplier declarations, to prove that their products meet RoHS standards.

Why RoHS Compliance Is Essential for Businesses

Market Access

RoHS compliance is not just important—it’s mandatory for selling electronic products in the European Union. Non-compliance can lead to products being barred from the EU market, which can be a significant financial hit for manufacturers.

Brand Reputation

Companies that ensure RoHS compliance are often viewed more favorably by consumers who are concerned about environmental impact and product safety. Compliance can thus enhance a company’s reputation and can be a strong selling point in marketing materials.

Avoiding Legal and Financial Penalties

Failure to comply with RoHS can result in legal penalties, including fines and restrictions on sales. Ensuring compliance helps companies avoid these penalties and potential negative publicity associated with non-compliance.

Conclusion

RoHS testing is a critical component of manufacturing and selling electronic products in today’s global market. It ensures that products are safe for the environment and for the people who use them every day. For companies, staying compliant with RoHS not only helps to protect the planet but also boosts their competitive edge in the marketplace. In essence, RoHS testing is not just about compliance—it’s about responsibility.

Note:- For more articles visit on backlinkaus.